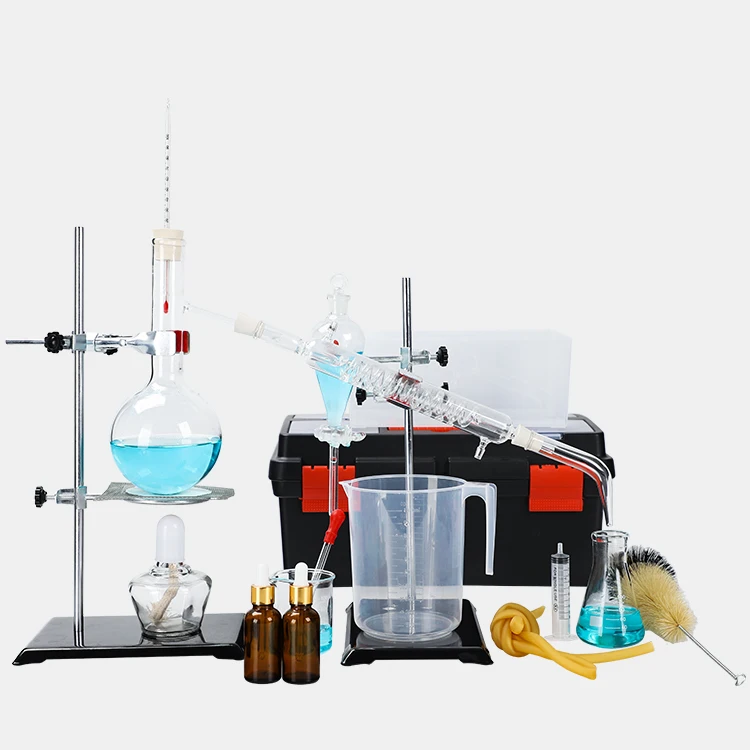

It is of vital importance to maintain and clean lab distillation equipment for excellent results in any experiment. We at Maihun understand what it means to take care of your tools and, how by doing so, you save time and money in the long run. Distillation gear might seem daunting, but don’t let that fear stop you from taking the plunge. Begin by understanding each piece of equipment and how it functions. This information will enable you to understand what should be cleaned and how to address any issues that arise. Maintenance keeps your gear shaped for accuracy and reliability.

How to Troubleshoot and Fix Them

Occasionally, not even top-of-the-line gear works the way it’s supposed to. If the system you set up for your distillation is off in some places, don’t be concerned! The first thing to do is see if there are any obvious problems. Check for leaks, which are possible if seals have gone bad or the connections aren't tight. A quick visual inspection is all you need to identify these issues. If you notice any stains or residue, it could be a sign that a component requires cleaning. Don't forget to power off and let the equipment cool before you begin troubleshooting. If you can’t find a problem, check the temperature settings. And the equipment sometimes fails to achieve the optimum temperature, potentially throwing off results. If you confirm all is well but nothing happens, the manual or a professional may help. It’s a good idea to just log any issues you’ve had and how you resolved them as well. Which means you can just get to learn your gear over time.

About Wholesale Distillation Equipment Maintenance and the Simplifications That are Required

And when purchasing distillation equipment, especially in quantities, it pays to invest the time in learning how to take good care of it. Here at Maihun we produce a range of high quality distillation equipment and knowing how to keep them in top shape saves you the most. First, you should always adhere to the manufacturer’s recommended cleaning guidelines. The safe products for the materials are to be used. Glass parts can, for instance, be washed in mild soap and water while metal shapes might need a different method. Inspect regularly for damage. That includes scuffs or rust, which can impair the efficacy of the distillation process. It's also important to store the equipment correctly and in dry safe places, not exposed to the elements where they can be damaged. Picking Up Spares If you see there are components that tend to either break or wear out regularly, have extras on hand. That could be a time-saver, and will help ensure your experiments don't get interrupted. When you take care of your equipment, then it will be reliable for all of your distillation needs.

How to Make Your Lab Distillation Equipment Last Longer

Maintaining your lab distillation equipment is crucial to its long life-span. The apparatus for distilling can be expensive, treat it accordingly. In the first place, we always know to refer to our user manuals before launching into things. The manual contains vital details on how to operate and maintain the device. You can prevent damage to it, if you follow the instructions. Second, be sure to keep your equipment safe. Store it in away from sunlight and heat. Materials break down more quickly in sunlight and heat. You should maintain it away from spotlessly clean and dry. Rust caused by moisture can destroy metal parts. Third, always verify that your equipment does not show wear or damage. If you notice a crack or something loose, fix it immediately. This could help you avoid further damage and save money in the long run. Fourth, be tender with your distilling apparatus. When connecting or disconnecting parts, make sure not to apply too much force. When not in use, the equipment must be treated gently in order to prevent breakage. Last, you’ve got to check out Maihun’s protective covers. They also can protect your gear from dust and debris when it’s not in use. You can do these things today and have your distillation equipment functioning properly for decades.

Top Place to Buy The Best Product for Cleaning Distillation Equipment

It’s very important that you find the right cleaning products for your distillation apparatus. The wrong products can ruin your gear. The first place to check for cleaning supplies is your local lab supply store. These retailers frequently have a selection of cleansing providers that are helpful for laboratory equipment. When you get to the store, inquire with an associate for some tips. They can steer you towards items made for distilling equipment. You can also buy online. There is a wide variety of cleaning products available on websites focused on lab supplies. You can read reviews and compare prices to find the best deals. Maihun also carries a variety of cleaning formulas that are effective for your distillation equipment. Be sure to visit their site for any special offers or packs. Pick cleaning products that are non toxic and biodegradable. These sorts of products are safer for you and better for the planet. As usual take a look at the labels so you can be certain that the products are safe to use for your equipment. You might also want to purchase cleaning brushes and cloths. You can use these tools to get into small areas so you don't miss a spot when cleaning. To summarize, the top cleaning products are available both in stores local to you or online or through Maihun. Certainly, you can use the products we discussed in the post on controlling wine’s distillation and fermentation odors that was written back in 1980 but do get products that are safe to be used with and proven effective for distillation equipment.

What Are the Best Ways to Clean Distillation Equipment?

To keep your distillation apparatus in good shape, it’s important to clean your gear properly. First, rinse your implements with warm water after each use. This helps to get out most of the residue that is left behind. This is something you should be doing right after you are done with the equipment. Drying residues can turn into a nightmare to remove. Now apply a fitting cleaner. You can either opt for a mild lab cleaner or water with vinegar. Vinegar is a natural cleaner and helps to dissolve those tough-to-remove gunk. Spray the washing solution onto the apparatus and allow standing for a few minutes. This gives the cleaner time to focus on any tough areas. Then, scrub the surfaces with a soft brush or cloth. Just make sure not to use anything too abrasive, which can damage the glass or metal components. And if you have spots difficult to reach, a pipe cleaner will go a long way. After you've cleaned the devices, rinse them well with warm water until no cleaning solution remains. When you rinse it out, allow your gear to air dry fully before putting it away. This prevents and moisture from leading to rusting or other damage. Be sure to clean the joints and seals too, as they can gather dirt and residues. You can use the cleaning tools developed by Maihun especially for distillation devices to facilitate the cleaning process even further. By following these efficient cleaning methods, your distillation system will remain in good condition for many years.

Table of Contents

- How to Troubleshoot and Fix Them

- About Wholesale Distillation Equipment Maintenance and the Simplifications That are Required

- How to Make Your Lab Distillation Equipment Last Longer

- Top Place to Buy The Best Product for Cleaning Distillation Equipment

- What Are the Best Ways to Clean Distillation Equipment?

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

ID

ID

SR

SR

SK

SK

SL

SL

VI

VI

MT

MT

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

GA

GA

HY

HY

BN

BN

MN

MN

SO

SO

KK

KK

MY

MY

UZ

UZ